Oil and Gas Industry Translation

Exploration and Processing

Global Content Solutions for Oil and Gas Industry

Introduction to Industry

The global economy is deeply intertwined with the exploitation of natural resources like oil, gas, and coal. These resources are the bedrock of traditional energy production, powering our world since the dawn of the industrial age. Electricity and other forms of power have been pivotal in driving technological progress and are crucial for a broad range of industries worldwide.

In contemporary times, there’s a discernible shift towards renewable energy sources as the world seeks more sustainable practices. Solar power, wind energy, and hydropower are becoming increasingly prevalent, introducing new layers of complexity to energy-related industries and services. This evolution is rapid and, at times, unexpected. Companies are recognizing that dwindling resources and fluctuating geopolitical landscapes necessitate greater supply chain diversification, including exploring new market opportunities abroad.

The energy sector, particularly those involved in power generation and fossil fuels, frequently relies on international suppliers and contractors. With the dynamic shifts in global policies, communication across borders and entities is becoming more critical. The demand for adept linguistic assistance is now more prominent than ever.

This is the arena where “REEID GCE – Global Content Engineering” enters, a seasoned entity offering expert linguistic solutions, backed by substantial experience in engineering disciplines related to energy. Their expertise is not just limited to language proficiency but extends to a deep understanding of the specific technical domains they serve.

Upstream | Midstream | Downstream Localization and Translation

The oil and gas sector demands a translation and localization service provider with a unique set of skills, including specialized education and a meticulous attention to detail. Handling documents for Upstream, Midstream, and Downstream sectors, our company serves clients globally, bringing invaluable insights into the intricacies of fossil fuel processes.

Our years of dedicated service have not only deepened our expertise in these complex industrial fields but also distinguished us for our precision and performance. Such proficiency ensures exceptional outcomes, setting us apart in a highly specialized and demanding market. Our understanding of the nuanced needs of the oil and gas industry propels us to deliver content that resonates accurately and effectively with each segment we serve.

How we do?

At REEID, we possess the essential resources to excel in the oil and gas industry’s unique translation and localization needs. Our infrastructure includes robust IT systems and extensive glossaries. Most importantly, we boast a remarkable talent pool. Our team members are not just skilled and well-educated; their deep industry insight has been honed through years of service with major oil and gas exploration and processing firms. As a tech-forward company, we enhance our translation and localization processes with an array of intelligent solutions, ensuring seamless, accurate translations and the cultural adaptation of your documents, free from errors.

What we usually do?

In the oil and gas exploration and refining sectors, the breadth of documentation requiring translation and localization is vast, catering to clear comprehension among all stakeholders. The types of documents we commonly handle include but are not limited to safety manuals, technical specifications, environmental impact assessments, legal contracts, operation manuals, project planning documents, and technical proposals. Each document type demands meticulous attention to industry-specific terminology and stakeholder communication preferences to ensure clarity and precision across all languages and cultures involved.

Integrated Safety Management System

- IMS Manual

- IMS Policies Procedures

- IMS Planning

- Management Commitment

- Document Control

- Control of IMS Records

- Responsibility, Authority and Communication

- Management review

- Customer-related processes

- Resource Management

Mechanical Completion & Certification

- Certification Administrator & Handover Manager

- Change Control

- Commissioning Authority

- Construction Maintenance Authority

- Data Input Sheets

- Defining System Limits

- Engineering & Projects

- Handover Certification Package Onsite Review & Flowchart

- Handover Certification Packs

- Handover Change Request

- Handover Change Request Flowchart

- Handover Sequence Of Events (Off Site) Flowchart

- Heat Treatment Report

- Inspection & Test Summary

- Joint Integrity Certificate

- Leak Test Certificate

- Magnetic Particle/Dye Penetrant Report

- Mechanical Completion Certificate

- Operating Authority

- Pipe Testing

- Piping Completion Certificate

- Plant Performance Certificate

- Punch List

- Radiographic Report

- Requirement For Change

- Responsibilities

- System Flow Sequence Of Events

- System Flushing Certificate

- System Handover Certificate

- System Safe Certificate

- Ultrasonic Inspection Report

- Weld Inspection

- Welding & Non Destructive Examination

- Welding Completion Summary

Commissioning & Start Up Procedures

- Apparatus For Use In Hazardous Areas

- Batteries & Battery Chargers

- Contactor Starter Circuit

- Current Transformer Magnetizing Curves

- Drying Of Electrical Rotary Machinery

- Earthing Bonding Procedure

- Fuse Switches Procedure

- Impulse Line Pressure Testing

- Installation Pipe Testing

- Junction Box Inspection

- Leak Testing

- Lighting & Small Power Distribution System

- Machinery Alignment

- Navigational Aids (Navaids)

- Neutral Earthing Resistor

- Oil Insulation Tests

- Powered Up Loop & Function Checking

- Power Transformers

- Programmable Controllers

- Pump-Compressor-Skid Mounted Unit Installation

- Switchboard & Busbars

- System Control (Function) Testing

- System Performance Trip Tests

- Testing Of Circuit Breakers

- Testing Of Protection & Meter Circuitry

- Trace Heating Tapes & Circuit

- UPS

- Vessels & Tanks Fabricated (Offsite)

- Vessels General Requirements

- Vessels & Tanks Modified (Onsite)

Process Procedures & Operating manuals

LNG plants are complex installations and comprehensive manuals need to be be produced to provide and maintain all the necessary information required for their safe and successful operation. Manuals are often split into the following levels:

· Company level

· Production operations level

· Installation level

Safety Procedures

- Abrasive Blasting Procedure

- Abrasive Wheels Procedure

- Accident Prevention Planning Procedure

- Adverse Weather Procedure

- Air Emissions Procedure

- Approval Of General Provisions Permit, Special Instructions & Other Safe Systems Of Work Procedure

- Asbestos Procedure

- Audit Procedure

- Blasting Procedure

- Breaking Containment Procedure

- Breathing Apparatus Procedure

- C.O.S.H.H. Procedure

- Cargo Handling Procedure

- Cartridge Tools Procedure

- Chemical Assessment & Selection Procedure

- Chemical Cleaning Procedure

- Chemical Management Procedure

- Colour Code Of Plant Equipment & Tools Procedure

- Colour Coding System Procedure

- Competent Person Procedure

- Compressed Gas Cylinders Procedure

- Concrete Operations Procedure

- Confined Space Procedure

- Confined Space Entry Procedure

- Construction HSE Plan Procedure

- Contractor Management Procedure

- Contractors Loss Prevention Procedure

- Control Of Temporary Installed Equipment Procedure

- Controlled Descent Escape Device Procedure

- Controlled Drug Procedure

- Crane Safety Procedure

- Crisis Management Procedure

- Delivery Acceptance & Storage Of Hazardous Materials Procedure

- Demolition & Blasting Procedure

- Disposal Of Waste Material Procedure

- Drilling & Completions Procedure

- Drinking Water & Sanitation Procedure

- Drug & Alcohol Abuse Procedure

- Eating & Messhall Standards Procedure

- Effluent Water Treatment Procedure

- Environmental Impact Assessment Procedure

- Electrical Safety Procedure

- Emergency & Evacuation Procedure

- Emergency Alarm Procedures

- Emergency Drills Procedure

- Emergency Planning & Response Procedure

- Environmental Incident Response Procedure

- Environmental Policy & Procedures

- Environmental Training Procedure

- Equipment & Pipe Testing Procedure

- Emergency Response Procedure

- Excavation & Trenching Procedure

- Fall Prevention Procedure

- Fatality Reporting Procedure

- Fire Prevention Procedure

- First Aid Procedure

- Flammable & Combustible Liquids Procedure

- Forklift Safety Procedure

- Form Work & False Work Procedure

- General Safe Work Practices Procedure

- Grit Blasting & HP Cleaning Procedure

- Hand & Power Tools Procedure

- Handling & Storage Of Explosives Procedure

- Handling Of Chemicals Procedure

- Hazard Communication Procedure

- Hazard Identification Procedure

- Hazardous Material Handling Procedure

- Hazardous Materials Management Procedure

- Hazardous Substance Communication Procedure

- Health & Hygiene Procedure

- Hearing Conservation Procedure

- Heat Stress Prevention Procedure

- High Pressure Water Cleaning Procedure

- Hot Work Procedure

- Housekeeping & Sanitation Procedure

- HSE Assurance Procedure

- HSE Contingency Plan

- HSE Inspection Procedure

- HSE Leadership Procedure

- HSE Management Plan

- HSE Management Review Procedure

- HSE Performance Monitoring & Reporting Procedure

- HSE Site Orientation Procedure

- HSE Training Procedure

- Hydrogen Sulphide Procedure

- Incident Investigation & Reporting Procedure

- Incident-Accident Investigation Procedure

- Incident-Accident Reporting Procedure

- Inhibit Control Procedure

- Job Safety Analysis Procedure

- Land Transport Management Procedure.

- Lifting Equipment & Lifting Operations Procedure

- Lock Out Tag Out Procedure

- Long Term Isolation Procedure

- Loss Prevention Program

- LPG Procedure

- Man Riding Basket Procedure

- Management Of Policies & Procedures.

- Marine Control Procedure

- Marine Safety Procedure

- Mechanical Equipment Procedure

- Medical Preparedness Procedure

- Mobile Crane Procedure

- Near Miss Reporting Procedure

- Noise Emission Testing Procedure

- Occupational Injuries & Illnesses Procedure

- Office Safety Procedure

- Offshore Safety Training Procedure

- Oil Spill Response Procedure

- Opening Of Process Systems Procedure

- Paint, Epoxy & Isocyanates Procedure

- Permit To Work Procedure

- Pest Control Procedure

- Piling Operations Procedure

- Plant & Equipment Inspection Procedure

- Potential Hazards & Impacts. Procedure

- PPE Procedure

- Pre Commissioning Operations Procedure

- Pressure Testing Procedure

- Project HSE Plan Development Procedure.

- PTW Auditing Procedure

- Radioactive Source Handling & Storage Procedure

- Radiography Procedure

- Recirculated Water Procedure

- Red Spade Procedure

- Respiratory Protection Procedure

- Rigging Procedure

- Risk Assessment Guideline

- Risk Assessment Procedure

- Risk Management Procedure

- Roofing Work Procedure

- Safe Blinding Procedure

- Safe Systems Of Work Procedure

- Safety Signs & Barriers Procedure

- Safety Training Procedure

- Scaffolding Procedure

- Security Procedure

- Severe Weather Procedure

- SIMOPS Procedure

- Site Inspection Procedure

- Site Planning & Housekeeping Procedure

- Small Tools & Equipment Procedure

- Steel Erection Procedure

- Suspended Work Baskets Procedure

- Task Risk Assessment Procedure

- Temporary Workshops & Storage Room Containers Procedure

- The Addition Or Removal Of Plant & Apparatus To Or From The System Procedure

- The Use Of Safety Signs & Signals Procedure

- Toolbox Talk Procedure

- Traffic Management Procedure

- Vehicle Safety Procedure

- Waste Management Procedure

- Waste Management & Recycling

- Welding, Cutting & Brazing Procedure

- Woodworking Machinery Procedure

- Workforce Welfare Management Procedure

- Working On Or Near Electrical Installations Procedure

- Working Over Water Procedure

Safety Training

- Abrasive Wheel Safety

- Advanced Safety Auditing

- Asbestos

- Chemical Management

- Compressed Gas Cylinder Handling

- Confined Space & Vessel Entry

- Cranes

- Defensive Driving

- Effective Safety Management

- Electrical Safety

- Emergency Response

- Excavations

- Fall Protection

- Fire Safety

- Fire Safety Training

- Fire Watchman

- Flagman & Banksman

- Forklift Truck Operations

- Gas Testing

- H2S Awareness & Escape

- Hand & Power Tools

- Hazard Identification

- HSE Management Of Contractors

- HSEMS Awareness

- Hydrogen Sulphide

- JSA Training

- Load Transportation Safety

- Lockout Tagout

- Making & Breaking Of Flanges

- Marine Safety Induction

- Office Safety

- Permit To Work Procedure

- Power Tools

- PPE

- Rigging & Slinging

- Risk Assessment (Major Hazards)

- Risk Management

- Scaffold Inspection

- Scaffolding

- Self Contained Breathing Apparatus

- Site Safety Induction

- Stair Ladders

- Static Electricity

- Suspension Trauma Safety

- Toolbox Talks

- Winter Driving Awareness

- Work Permit Training Issuer & Receiver

- Working At Height

Safe Work Instructions

- Adverse Weather

- Changing Gas Cylinders

- Communicable Diseases – Personal Hygiene

- Concrete Pumping

- Cyclonic Conditions

- Demolition

- Emergency Evacuation

- Environmental

- Erecting & Using Fixed Scaffolding

- Erecting & Using Mobile Scaffolding

- Exposure To Noise

- Fall Protection

- First Aid Log

- Fitness For Work

- Flammable Combustible Liquids

- Forklift

- Generator Refueling

- Hazardous Waste Handling

- Heat-Stress

- Hot Tapping

- Hotwork

- Housekeeping – Access & Egress

- Induction

- Lifting & Slinging

- Live Electrical: High Voltage

- Logout Tagout

- Manual Handling

- Mobile Cranes

- Night Work

- Operating Crane

- Operating Plant

- Orientation

- Personal Protective Equipment

- Radiography

- Remote & Isolated Work

- Rigging

- Safety & Accident Prevention

- Scaffold Permit

- Scaffolding

- Stacking & Storage Of Material

- Storage & Use Of Hazardous Substances

- Sunburn & Skin Cancer

- Suspended Basket

- Thermal Stress – Cold

- Thermal Stress – Heat

- Trenching & Excavations

- Using Compressed Air

- Using Electric Arc Welding Equipment

- Using Electrical Equipment

- Using Electrically Operated Tools

- Using Explosive Powered Tools

- Using Hand Tools

- Using Ladders

- Using Laser Survey Tools

- Using Oxyacetylene

- Using Small Powered Plant

- Welding & Cutting Drums And Vessels

- Work Close To Traffic

- Work Near Overhead Power Lines

- Work Near Plant

- Work Near Underground Services

- Work Over Or Near Water

- Working At Height

- Working With Asbestos

Technical Evaluations

- Competency Assurance

- Emergency Response Plan

- Environmental Management

- Health And Safety Management System Framework

- Health, Safety & Environment Rules

- HSE And Security Hazards And Managing Risks

- HSE Audit

- HSE Management System

- HSE Performance Measuring

- HSE Policy

- HSE Regulatory Compliance

- HSE Training

- Incident Reporting And Investigation Procedure

- Inventory Of All Hazardous Chemicals And Other Hazardous Substances

- Medical Examination For All Employees Before They Are Employed

- Personal Protective Equipment (PPE)

- Risk Register

- Safety Observation

Toolbox Talk

- Accident Causes

- Advice To Employees

- Advice To Supervisors

- Banksmen & Riggers

- Changing Tires

- Checklist For Safe Use Of Chemicals On Site

- Compressed Gas Cylinders

- Confined Spaces

- Electrical Safety

- Emergency Evacuation Procedure

- Excavations

- Fire Prevention

- Forklift Trucks

- Hand Tools

- Heat Stress

- Horseplay

- Housekeeping

- Injury Reporting

- Lifting & Manual Handling

- Lifting & Rigging

- Lockout Tagout

- Material Handling Storage

- Near miss reporting

- Oxygen & Acetylene Welding

- Pinch Points

- Pre-Task Toolbox Talk

- Radiography & X-Rays

- Reduce Injuries

- Risk Checklist & Toolbox Talk

- Sand Blasting

- Scaffolding

- Towing Vehicles

From 2021 to 2024, we have expertly managed an extensive array of documentation, translating millions of words for industry giants such as Samsung Engineering, Saipem, Petrofac, Bechtel, and Thai Oil. Our work has spanned a variety of tasks associated with processing and exploration, involving the translation of HAZOP analyses, various manuals, pertinent contracts, safety datasheets, and a myriad of other specialized content types.

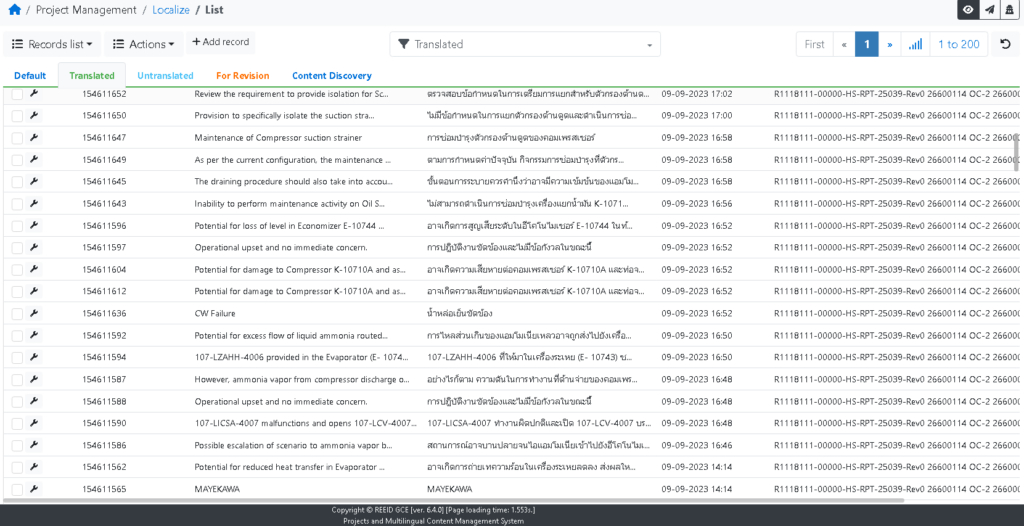

Our commitment goes beyond mere translation. We have engaged in intricate ancillary tasks, including the programmatic management of document content to maintain consistency with technical layouts, tags, translation memories (TMs), and more. This vast volume of work is executed on our proprietary localization platform, which has been custom-developed by our in-house programmers under the strategic direction of our management team. This platform is continually used to deliver our complex services.

DATA SECURITY MEASURES

We prioritize the security of your data and our resources with exceptional diligence. Recognizing the need to protect certain documents and information from unprivileged individuals and automated systems, we have implemented rigorous safety controls and methodologies across our business units:

- We don’t use cloud based storage services (Google, Dropbox etc.) for sensitive data ( unless specified otherwise by Customer)

- We don’t use outsourced SMT (Statistical Machine Translation Engines) unless specified otherwise by Customer

- We don’t Build, Train, and Deploy Machine Learning systems and process datasets with use of cloud based third parties engines unless specified otherwise by Customer

- We are using only secured transmission protocols for external communication

- Strong files encryption within local storages and Distributed DMS

- Robust access privileges to our online platforms (profiles, roles, sharing rules)

- Access control on databases records level

- MFA authentication for all access to sensitive data

- Data destruction and disposal procedure in place

- Intrusion prevention system

- Multilayer data loss prevention (DLP) systems and procedures in place

- Data anonymization procedures (important while outsourcing projects)

- Regular Security & Confidentiality Audits

- Data Centers in Europe and Asia (depending on data security requirements, certain DC is selected)

- Full GDPR compliance

- Data protection compliance in line with regulations of the countries out of Euro-zone